Commercial Flagpoles

Shop and compare a full line of In-Ground Aluminum Commercial and Residential Flagpoles.

Manufactured in USA.

Shop our Flags, Flagpoles and Flagpole Components

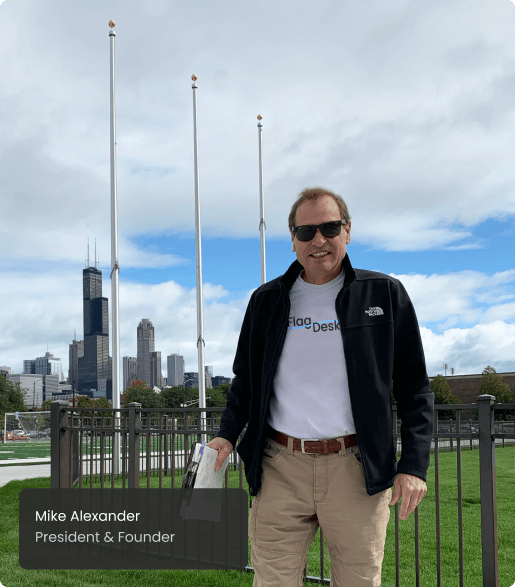

About Us

FlagDesk works with architects, engineers, general contractors and individuals to ensure they have the right flagpole for their project.

FlagDesk specializes in flagpole selection – we adhere to engineering and wind load specifications. With expertise in: project bids, Division 10 7500 Flagpoles, flagpole submittals, professional engineering stamps, and installation methods, FlagDesk can offer solutions for any new construction project.

If that's not enough, the president of FlagDesk, Mike Alexander, has 30+ years in the business. FlagDesk will deliver the eye-catching flag display you are looking for!